Fracture Mechanics in Sour Service: Some Characterization Tests on SENT and SENB Specimen

专职专家

Rodolfo AmorielloWith extensive knowledge of analytical chemistry methods used for metallic and non-metallic materials, Rodolfo在化学分析和腐蚀测试方面拥有20年的经验.

目前, there are no clear guidelines on how to establish 断裂韧性 of pipelines in sour service environments. 我们的专职专家, Rodolfo Amoriello has carried out research to develop a better understanding of how the SENT test technique influences 断裂韧性 in sour service.

对测试的需求越来越大 断裂韧性 特别是在管道中 在酸性环境中. 酸性流体和气体的存在会导致管道恶化, 其影响范围从微小的针孔泄漏到灾难性的破坏.

介绍

Single-Edge Notched Tension (SENT) specimens are known to generally give less conservative parameters than Compact Tension (CT) or Single-Edge Notched Bend (SENB) for 工程关键评估(ECA) and 适合服务(FFS) 用于分析含有缺陷的管道弯曲时的计算.

在一般情况下, 碳钢, an increase in H2S concentration causes a 断裂韧性 decrease mainly due to the hydrogen embrittlement effect.

因此, the maximum tolerable flaw size (predicted by ECA calculations) is smaller when the H2S effect is taken into consideration. 关于FFS, this means for the same defect size an initial localization on the Failure Assessment Diagram is closer to (or even inside) the critical zone. Execution of SENT tests in sour service is expected to give data for ECA/FFS analysis that is closer to the real material behavior, balancing the less conservative parameters typical of the specimen geometry used with the more stringent conditions of the corrosive environment.

Some characterization tests have been designed and tested to make a comparison between the J-R curves in air against the J-R Curves 在酸性环境中 for both SENT and SENB samples. 本文讨论了SENT试验的结果.

测试设置

材料选择, mounting procedure and sample preparation before executing the test must guarantee the absence of any contamination and the continuous presence of H2S bubbling during all test phases; from pre-loading to the end of the fracture mechanics test. Asymmetric vessels have been designed to guarantee the correct solution concentration according to a standard or a client's specification. 因为测试是在H2S冒泡的情况下进行的, special attention is given to ensure the correct health and safety conditions and protection of the operators and the measurement apparatus.

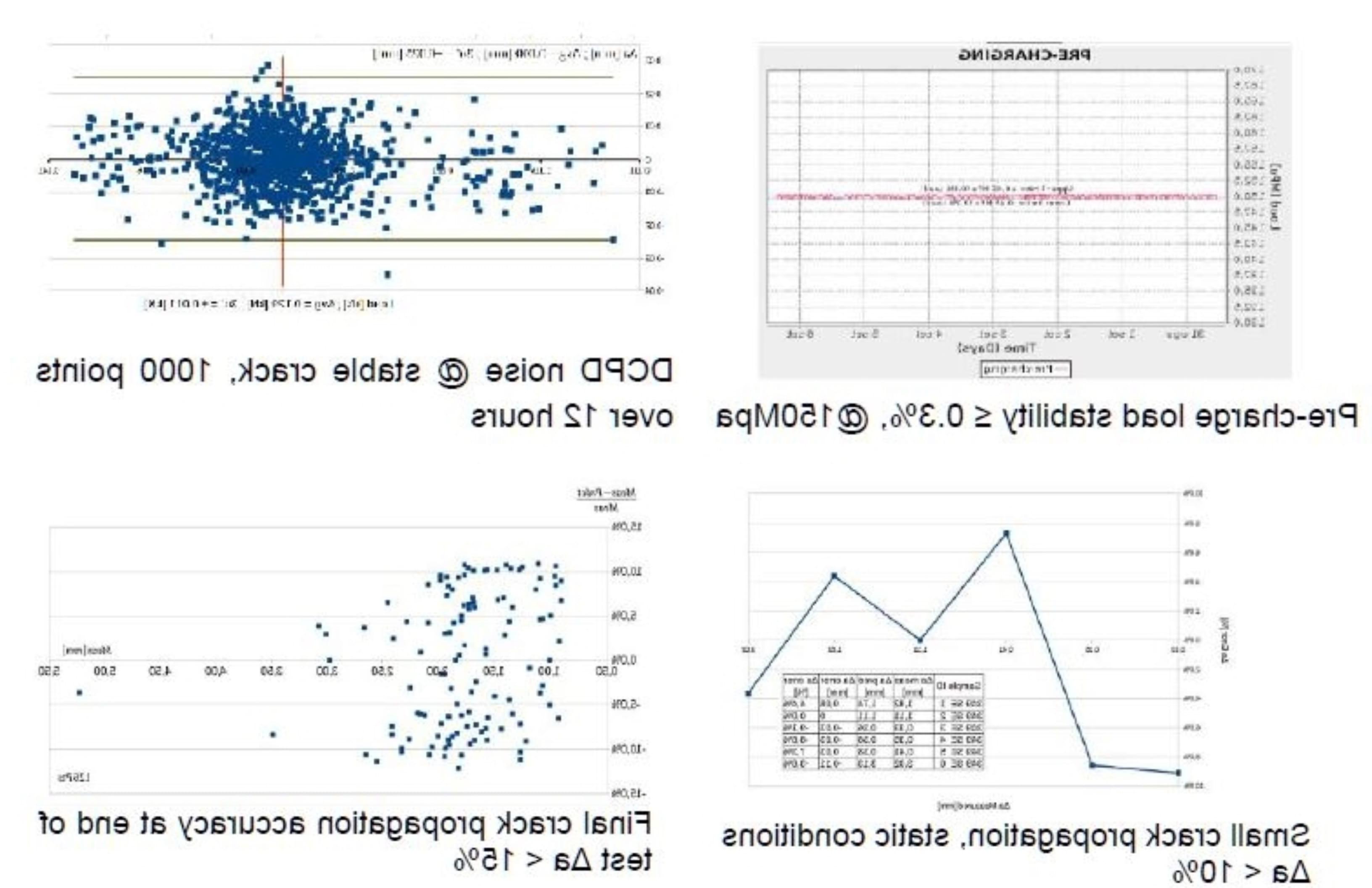

断裂力学试验前, samples are pre-charged in H2S at pre-selected loads using special loading frames able to apply constant load up to 250kN. 在整个预充药期间监测载荷稳定性,以确保裂纹稳定性. 当出现裂纹扩展并对试样进行分析时,停止试验. 数据日志被保存,以备将来调查和检查. Crack monitoring is achieved using a Direct Current Potential Drop (DCPD) system electronically switched sequentially and cyclically among all pre-charging frames. DCPD电子放大器, filters, duty cycle and sampling frequency have been designed to have high accuracy over all the measurement period. The software was developed to control the DCPD system allows a real-time estimate of the crack growth during the test. 预充期一般为1周.

Samples are removed from the pre-charging frame and moved to the fracture mechanics test frame using a trolley designed to guarantee the continual presence of H2S and safe handling of the testing arrangement.

Fracture mechanics test are then conducted at very low speeds with a minimum of 3.16 10 -3 M / M / s用于SENT样品,使用DCPD系统. 对于SENB样品,最小速度为5 10-3M√m /s. 溶液温度为240℃±20℃.

整个测试持续时间通常在8到12小时之间.

测试设备特性

To guarantee data accuracy, many tests have been carried out for comparison on the test apparatus. Some examples are reported in the diagrams below using the following test conditions:

-测试溶液:NACE测试液. B, H2S 0.2 bar partial pressure (30%) balanced with N, max O2 < 10 ppb

-预加载:1周@ 150MPa

– F.M.Speed: 0.1√(只有WM).4 √ ,4.0√[热影响区(HAZ)和焊缝(WM)]

测试结果

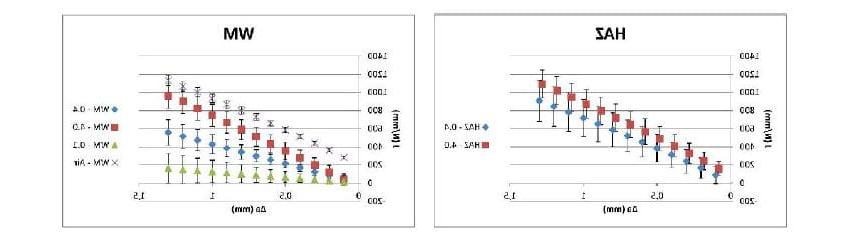

SENT样品的测试结果, X65, BxB 36 mm, 表面缺口NQ, 从帽侧开始, HAZ和WM如图J-R曲线所示. 每个样品使用相同的焊接团队进行焊接, 使用相同的设备和相同的材料批次. Each series of experimental points represents the mean and standard deviation of the data from 10 samples. 另外10个样本在空气中的WM中进行了测试以进行比较.

The combined effect of sour environment and of different test speeds is evident: the higher the speed the closer the data are to curves "in air".

预加载和酸性条件下试验的相关影响如下:

增加了至少两倍的数据相对于“空中”曲线的离散度

– for all samples "in sour conditions" J is almost 0 at the first part of propagation curve (Δa from 0 to ≈ 0.1 mm).

在发送大样本的情况下, 那些被测试的人, the effect of residual stresses becomes relevant for samples subjected to pre-charge at relatively high loads for one week. 在资格预审的早期阶段, 仅在预加载几天后就观察到自发裂纹扩展, @150MPa. Subsequent residual stress measurements highlighted machining for samples preparation and pre-strain at 0.4%的人只是降低了他们的价值.

结论

Fracture mechanics test in sour conditions (H2S) after a pre-charging period in H2S solution was demonstrated to give results closer to the real material behavior in the application.

A dedicated test procedure and apparatus has been designed and characterized to guarantee reliable results that can be used for FFS / ECA.

Experimental data show a significant effect of sour conditions both for pre-loading and for fracture mechanics. Different test speeds have been shown to have a significant influence on the J-curve determination in presence of H2S.

有关send的更多信息, SENB, 断裂韧性, 断裂力学测试或联系Rodolfo Amoriello进行进一步讨论, please 立即im体育APP.

找到相关的 资源

来自Element的更多信息

断裂力学下载

Read our article to learn the different test methods and sample geometries used to determine 断裂韧性.

工程关键评估(ECA)

我们拥有世界领先的油田适用性服务(FFS) & 天然气im体育平台app下载

酸性应用腐蚀

Find out how Element’s laboratories use hydrogen sulfide and other sour gases to replicate the highly corrosive conditions found in oil and gas environments.

断裂韧性测试

Find out how Element utilizes its 断裂韧性 testing capabilities and expertise to predict and prevent potential pipeline cracking and failure.