多轴疲劳分析

多轴疲劳分析

多轴疲劳分析 replicates the load and stress conditions of real-world service environments in controlled laboratory settings to develop safer, more reliable, 可靠的材料和部件.

These 机械测试 在评估复杂设计结构中发挥关键作用, components, 这些材料, 在它们的使用寿命内, 在航空航天等广泛的im体育平台app下载中承受复杂的多轴载荷, agriculture, 还有交通 发电 以及土木工程.

The complex stresses that occur during operation are examined under static and dynamic operational loads to assess the impact of fatigue 并确定准确的使用寿命预测. The testing is crucial for effectively simulating the mixed-mode loading environments and measuring in-plane stresses in both the X and Y axes of advanced materials and components.

劳斯莱斯的多轴测试传统

通过劳斯莱斯和Element的合作, 工程师团队现在提供高质量的多轴测试能力, 采用最先进的技术,并辅以独特的专业知识, 面向多个im体育平台app下载的制造商.

The team at the 劳斯莱斯在德国达勒维茨的测试设施, has been using multiaxial testing for many years as a crucial part of the design and qualification process for critical aerospace components. The testing is frequently used to support a high-profile lifting program for high-pressure turbine discs and features associated with Group ‘A’ Critical Parts using hot multiaxis rigs. The primary purpose is to test a sub-element of the fir-tree connection between the turbine disc and the turbine blade.

The loads in the fir-tree connections have a direct effect on both the blade and disk’s lifespans. When accurately designed, these rotating parts of the turbine can result in improved performance;

- 更低的运营成本

- 更长的使用寿命

- 减少飞机废气排放

- 减少对环境的影响

圆盘是最容易开裂的发动机部件, this rigorous safety testing is a critical part of the design and qualification process.

使用多轴钻机, forces are applied to the test article from rectangular vectors with additional torque to create a complex load pattern. 然后用光学应变测量方法分析了载荷模式. This is then used to replicate the fretting fatigue mechanisms acting on the fir-tree connection.

重新定义安全界限,实现更好的设计

多轴试验台常用于分析在役问题, helping to provide a better understanding of the risks associated with an in-service issue and, 因此,重新定义安全界限的能力. In consequence, 它可以实现更好的设计, 哪些可以通过其在试验台上的有效性进行分析和批准.

Energy, aerospace, 运输客户可以将RIGS用于各种各样的应用, including determination of frictional break forces with various normal forces and tests under various environmental conditions.

测试适用于各种各样的材料, 包括金属,如高抗拉强度钢, 金属合金,如铝合金, 镁合金, 还有钛合金, polymers, ceramics, 弹性体复合材料, textiles, concrete, 先进的建筑材料.

These materials can be tested for a wide range of applications depending on the industry.

The automotive industry frequently uses multiaxial testing to validate new material models for sheet metal or composite components to meet demanding fuel economy targets and increased safety requirements. The construction industry uses it to study advanced materials to allow for more complex designs and meet challenging environmental needs. The 发电 工业上采用多轴试验进行大规模试验 wind turbine structures that are to be positioned in harsh offshore environments whilst the oil and gas industry uses it to test for pipeline components that will allow exploration in areas that are difficult to reach.

最先进的多轴分析设备模拟现实世界的条件

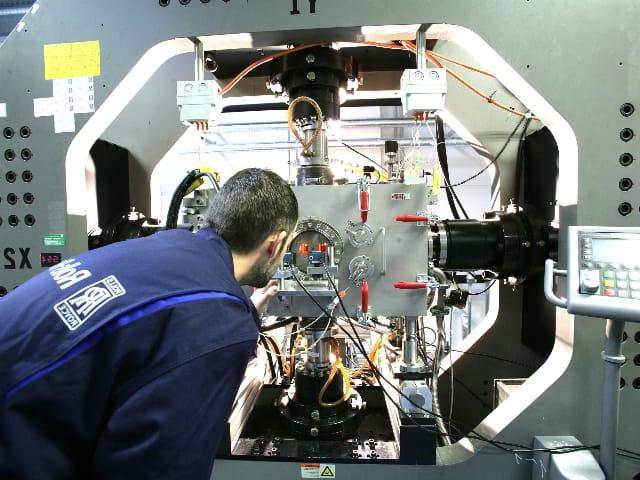

The 劳斯莱斯Dahlewitz 站点大量投资于最先进的多轴测试设备, 包括MTS平面双轴伺服液压系统. Planar双轴机械设备模拟了现实世界的条件, stressing the specimen in multiple directions while allowing the test engineers to exert a high level of control over the process to produce accurate, 可重复的结果.

MTS技术允许根据需要定制测试. This could, for example, 专注于断裂力学和疲劳裂纹扩展, examining how quickly a crack will grow and how soon it will reach a critical size under various loading conditions. Or it may be used to run damage tolerance tests to measure crack growth from a large hole in the material, 然后修复损伤,看看修复效果如何, 或者测试同一个洞可以修复多少次.

使测试能够在各种服役条件下进行, environmental simulation systems complement the planar biaxial equipment to apply extreme temperatures, vacuum, 以及被测样品的湿度.

用于非环境测试, the planar biaxial frames can be outfitted with environmental chambers for testing at cold temperatures using liquid nitrogen (or other liquefied gases if required), 惰性氛围, vacuums, and both vacuum and high temperature using furnaces or induction heating inside of a vacuum chamber. High-temperature testing can also be accomplished in the air using either furnaces or induction heating with the available temperature range in the environmental furnace ranging from room temperature to 800°C.

劳斯莱斯和Element的优势

Rolls-Royce engineers ensure every step in the testing program is carefully planned before being executed, 使制造商能够为任何潜在问题做好准备. 准备测试时, 团队确保所有步骤都已采取,以确保过程顺利进行, taking into consideration issues such as the exact definition of the required load axis and their alignment requirements to each other, 以及可用空间的测试文章, and any potential environmental requirements such as vacuum and temperature uniformity/gradients and main fixture interfaces.

The MTS technology ensures superior alignment preventing unintentional bending stress that can put the specimen at higher risk of buckling or early failure, 尽量减少潜在的试样损伤.

作为测试过程的一部分, the Rolls-Royce experts will verify the failure mechanism and recommend how to identify resolutions. The team can then work closely with the component or material manufacturer to start proof testing an improved design to provide a tailored solution that will prevent future in-service failures.

有关多轴测试的更多信息,请 请联系Element today.

Find related Resources

相关服务

劳斯莱斯卓越中心

劳斯莱斯卓越中心, 位于达勒维茨, Germany, 是领先的材料测试供应商吗, 包括多轴疲劳能力, 组件振动, 复合材料叶片, 以及大规模自旋测试

复杂结构的振动测试

Element and Rolls-Royce have joined forces in a unique collaboration to offer their vibration services to a wide range of industries from aviation and automotive to rail and oil and gas.

使用故障分析来管理运行中的故障

在服务中发生事件时, it is therefore vital that the reason behind how and why a material or product has failed is established as quickly as possible, 找到解决方案并立即实施.

Fatigue Testing

Find out how Element's fatigue testing labs help companies meet quality requirements and create safer, stronger, 更成功的零件和产品.